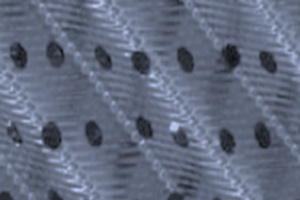

Structured Packing is made of several packing with different geometrical shape and corrugation angle. According to different corrugation angle, it can be divided into X type and Y type. X type structured packing has small pressure drop and the Y type structured packing has better mass transfer property.

Standard Type

Increasing Capacity

Increasing Efficiency

| Structured Packing | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Surface Area, m2 / m3 |

64 | 84 | 175 | 200 | 220 | 250 | 300 | 350 | 450 | 500 | |

| Inclination | |||||||||||

| 45° | 64 Y | 125 Y | 175 Y | 200 Y | 220 Y | 250 Y | 300 Y | 350 Y | 450 Y | 500 Y | |

| 60° | 64 X | 125 X | 175 X | 200 X | 220 X | 250 X | 300 X | 350 X | 450 X | 500 X | |

Wire Gauze Type

Wire gauze structured packing is made of various metal wires and then woven into wire gauze. This is the most widely used type of structured packing especially for processing specialty chemicals, pharmaceuticals and temperature-sensitive materials because it has advantages of high effectiveness, low pressure drop and large flow rate. It is also suitable for precise distillation and vacuum distillation devices. However, wire gauze structured packing is not suitable for fouling services and strongly corrosive media.

| Wire Gauze Structured Packing | Bulk Density, kg / m3 | Surface Area, m2 / m3 |

|---|---|---|

| 250 X | 120 | 250 |

| 500 X | 240 | 500 |

| 700 Y | 340 | 700 |

Grid Type

Grid structured packing are designed for severe services that are prone to plugging, coking, erosion and containing solids because it can provide high heat transfer efficiency, high mechanical strength and antifouling characteristics. Moreover, grid structured packing has robust mechanical structure, fabricated in modules for ease of installation and cleaning.

| Grid Packing | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Surface Area, m2 / m3 | 40 | 45 | 55 | 64 | 90 | ||||||

| Inclination | |||||||||||

| 45° | 40 Y | 45 Y | 55 Y | 64 Y | 90 Y | ||||||

| 60° | 40 X | 45 X | 55 X | 64 X | 90 X | ||||||